Services

Wellhead Valve Preventative Maintenance

Your wellhead is is the focal point of profitable operation of a lease.

Underperforming wellhead valves can lead to costly repairs, unexpected downtime and even injury to personnel.

Valves are constantly exposed to the harshest of conditions, leading to grease breakdown, grease washout, corrosion, packing degradation and hard operation.

Routine valve maintenance is a low cost service that can help combat these points of failure and prevent downtime.

Valve Greasing

Our team visits each of your locations at the specified interval and performs valve greasing service. We can service all makes of gate and ball valves including WKM style, Cameron style, McAvoy and more.

We stand ready to service your wellhead valves, pipeline valves and salt water disposal/injection (SWD) valves.

Field-Capable Repair

Durbin Enterprises can effect field repairs such as plastic injection, shear pin repair, grease zerk replacement and other field-capable repairs.

Valve Inspection and Reporting

Some valves may present hazards or problems that are beyond field repair. We will identify these valves and report so that your team can be aware of issues that may need to be addressed in the future.

Examples of such issues might be physical external damage, leaking flanges or internal valve issues.

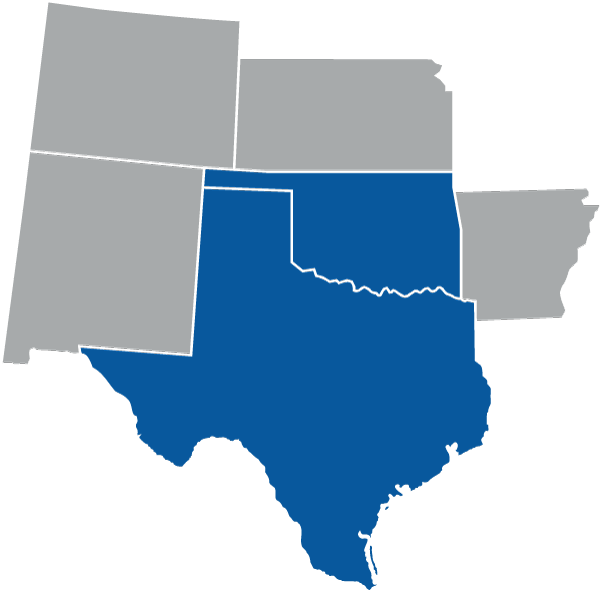

Serving Oklahoma, Texas and Beyond

Durbin Enterprises currently performs valve maintenance services in Oklahoma and Texas.